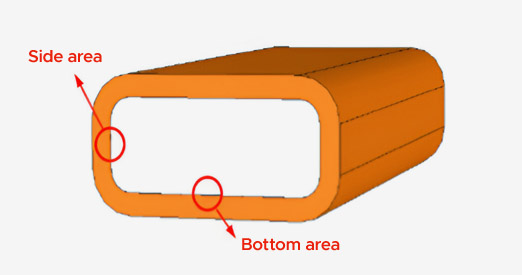

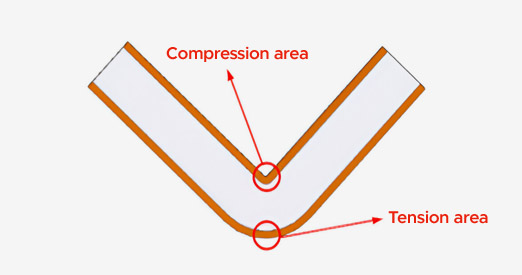

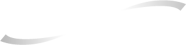

- ① Molten copper liquid enters a vacuum composite furnace to form a copper pipe, and then molten aluminum liquid enters the copper pipe.

- ② Aluminum and copper on the inner wall of the surface of the molten copper pipe melt together at high temperatures to form a surface (interface) fusion.

- ③ Copper and aluminum that formed the surface fusion form a new compound through a chemical reaction, and a new bond (metallurgical bond) between atoms is completed, which results in a surface (interface) reaction.

- ④ The two metal liquids pass through the composite mold and undergo accurate cooling for the second and third time to form a stable crystal zone (this zone is a sealed zone filled with metal liquid and gas cannot enter), and when the solidified bar (sheared billet) is taken out through the moving processor, the copper aluminum billet is completed.

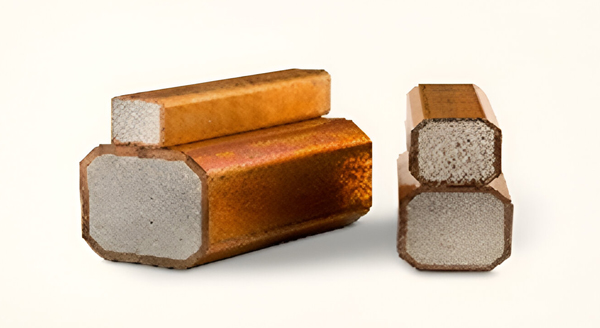

CCA

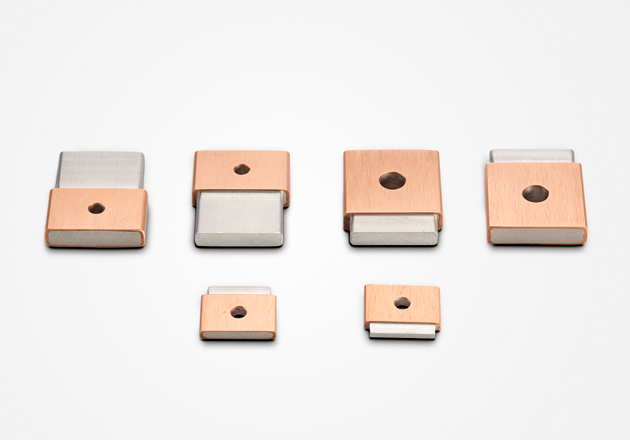

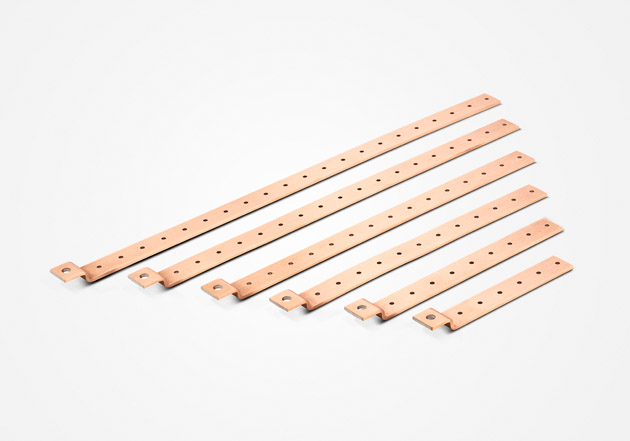

Copper Clad Aluminium Bimetal Horizontal continuous casting copper-clad aluminum busbar

Benefits of Copper Clad Aluminum Busbar

- Cost savings of over 20% as an alternative to copper busbars

- Easier workability due to 50% lighter weight compared to copper busbars

- Reduced transportation costs due to lighter weight, reducing logistics costs

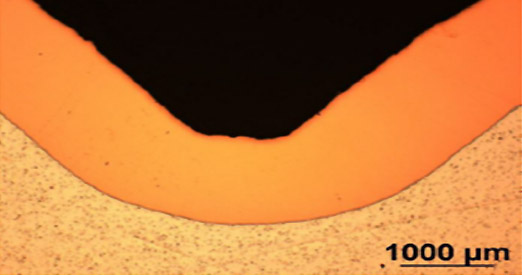

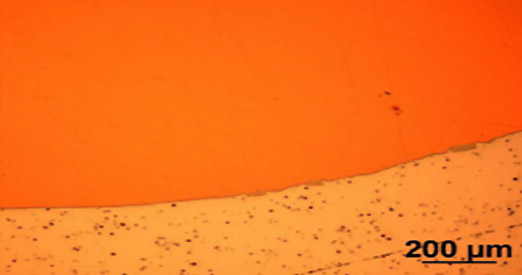

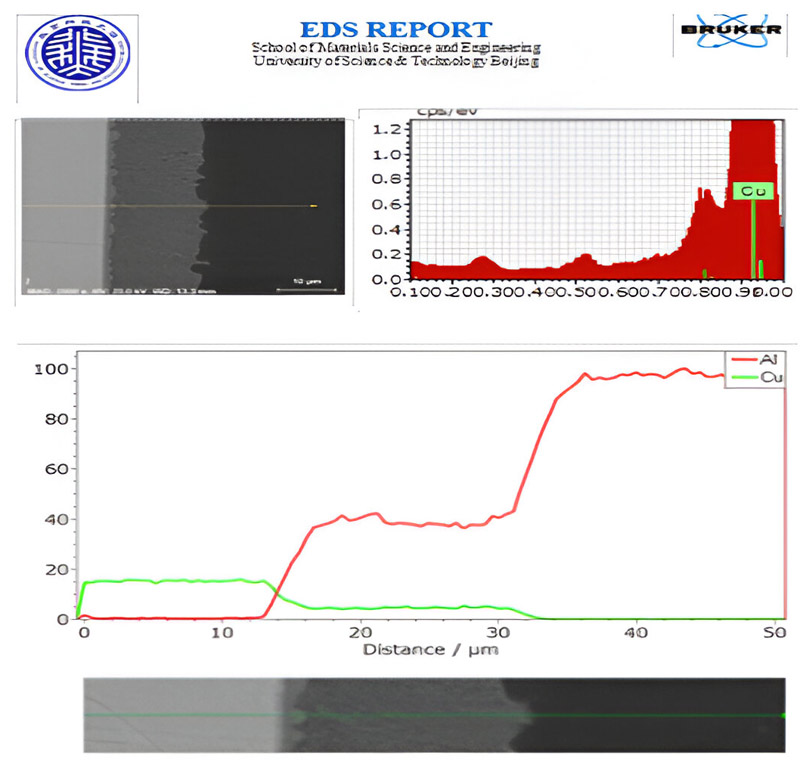

Analysis of busbar joint surface of horizontal continuous casting method

SEM and EDS interface analysis results

Interface joint interface scan photo

IMC (Intermetallic Compound/Intermetallic compound) management 20~30㎛ (GBT standard: 30㎛ or less)SEM (Scanning Electron Microscope)

A measuring device that can magnify 200,000 times with an electron microscope, and observes the sample by electronic imaging through various types of electron flux scanning or bombardment.EDS(Energy Dispersive Spectrometer)

A probe that analyzes a spectrum of energy, it is generally mounted on an electron microscope to analyze the characteristics of the electron beam emitted from a variety of materials and measure the chemical element classification and content.Technical specifications

Move left and right to check.

Move left and right to check.| BUSBAR | Resistance (Ω.㎟/m) |

Conductivity (I.A.C.S/%) |

Tensile strength (Mpa) |

Current density (g/㎤) |

CU&AL Bonding strength (Mpa) |

|---|---|---|---|---|---|

| CCA | 0.01298~0.02523 | 70~81 | ≥110 | 3.94/4.25/4.56 | ≥50 |

| CU | 0.012741 | 100 | ≥250 | 8.89 | |

| AL1070 | 0.027808 | 62 | ≥75 | 2.7 | |

| AL6101 | 0.028976~0.031347 | 55~59.5 | ≥85 | 2.7 |

Specifications according to copper volume ratio

Move left and right to check.

Move left and right to check.| Composite layer volume ratio (%) |

Tensile strength (Mpa) |

Elongation (%) |

Density (g/㎤) |

Interfacial bonding strength (Mpa) |

Resistance (Ω.㎟/m) |

Volume conductivity (≥% IACS) |

|---|---|---|---|---|---|---|

| 20 | ≥110 | ≥25 | 3.94 | ≥40 | 0.0255 | 67.6 |

| 25 | ≥115 | ≥30 | 4.25 | ≥40 | 0.02498 | 69 |

| 30 | ≥120 | ≥35 | 4.56 | ≥40 | 0.02424 | 71.1 |

※ Post-heat treatment condition

Copper Aluminum busbar allowable current table

Move left and right to check.

Move left and right to check.| Thickness/mm | Width/mm | Volume ratio 20% | Volume ratio 25% | Volume ratio 30% |

|---|---|---|---|---|

| AC | AC | AC | ||

| 3 | 15 | 193 | 198 | 203 |

| 25 | 292 | 300 | 308 | |

| 20 | 241 | 247 | 254 | |

| 30 | 333 | 342 | 351 | |

| 40 | 420 | 431 | 443 | |

| 50 | 497 | 510 | 524 | |

| 4 | 15 | 219 | 225 | 231 |

| 20 | 283 | 291 | 299 | |

| 25 | 342 | 351 | 360 | |

| 30 | 391 | 402 | 413 | |

| 40 | 500 | 514 | 528 | |

| 50 | 588 | 604 | 620 | |

| 60 | 689 | 708 | 727 | |

| 70 | 780 | 801 | 823 | |

| 80 | 864 | 887 | 911 | |

| 100 | 1060 | 1089 | 1119 | |

| 5 | 15 | 258 | 265 | 272 |

| 20 | 325 | 334 | 343 | |

| 25 | 387 | 397 | 408 | |

| 30 | 443 | 455 | 467 | |

| 40 | 568 | 583 | 599 | |

| 50 | 669 | 687 | 706 | |

| 60 | 785 | 806 | 828 | |

| 70 | 898 | 922 | 947 | |

| 80 | 1006 | 1034 | 1062 | |

| 100 | 1236 | 1269 | 1304 | |

| 6 | 15 | 277 | 284 | 292 |

| 20 | 357 | 367 | 377 | |

| 25 | 429 | 441 | 453 | |

| 30 | 490 | 503 | 517 | |

| 40 | 618 | 635 | 652 | |

| 50 | 746 | 766 | 787 | |

| 60 | 871 | 894 | 918 | |

| 70 | 1000 | 1027 | 1054 | |

| 75 | 1071 | 1100 | 1126 | |

| 80 | 1104 | 1134 | 1164 | |

| 100 | 1344 | 1380 | 1417 | |

| 120 | 1563 | 1605 | 1648 | |

| 150 | 1760 | 1807 | 1856 | |

| 8 | 15 | 332 | 341 | 350 |

| 20 | 430 | 442 | 454 | |

| 25 | 511 | 525 | 539 | |

| 30 | 587 | 603 | 619 | |

| 40 | 728 | 748 | 768 | |

| 50 | 874 | 898 | 922 | |

| 60 | 1018 | 1046 | 1074 | |

| 70 | 1161 | 1192 | 1224 | |

| 75 | 1244 | 1274 | 1306 | |

| 80 | 1297 | 1332 | 1368 | |

| 100 | 1564 | 1606 | 1649 | |

| 120 | 1812 | 1861 | 1911 | |

| 150 | 2070 | 2126 | 2183 | |

| 10 | 15 | 401 | 412 | 423 |

| 20 | 493 | 506 | 520 | |

| 25 | 577 | 593 | 609 | |

| 30 | 663 | 681 | 700 | |

| 40 | 831 | 853 | 877 | |

| 50 | 994 | 1021 | 1048 | |

| 60 | 1153 | 1184 | 1216 | |

| 70 | 1309 | 1345 | 1381 | |

| 75 | 1403 | 1438 | 1471 | |

| 80 | 1458 | 1497 | 1537 | |

| 100 | 1738 | 1785 | 1833 | |

| 120 | 2013 | 2068 | 2124 | |

| 150 | 2283 | 2345 | 2408 | |

| 12 | 15 | 448 | 460 | 472 |

| 20 | 550 | 565 | 581 | |

| 25 | 656 | 673 | 691 | |

| 30 | 743 | 763 | 784 | |

| 40 | 918 | 943 | 968 | |

| 50 | 1095 | 1125 | 1155 | |

| 60 | 1267 | 1301 | 1336 | |

| 70 | 1441 | 1480 | 1520 | |

| 75 | 1543 | 1582 | 1623 | |

| 80 | 1594 | 1638 | 1682 | |

| 100 | 1893 | 1944 | 1996 | |

| 120 | 2193 | 2252 | 2313 | |

| 125 | 2265 | 2335 | 2407 | |

| 150 | 2718 | 2784 | 2846 | |

| 15 | 50 | 1332 | 1358 | 1375 |

| 60 | 1589 | 1624 | 1657 | |

| 80 | 2084 | 2123 | 2159 | |

| 90 | 2350 | 2389 | 2434 | |

| 100 | 2615 | 2680 | 2755 | |

| 120 | 3018 | 3093 | 3175 | |

| 150 | 3290 | 3392 | 3497 |

- Environment temperature 25℃, temperature rise 50K, AC frequency 60Hz, sample vertical test allowable current

- For horizontal test, when width ≤ 60mm, the data in the table is *0.95; when width > 60mm, *0.92

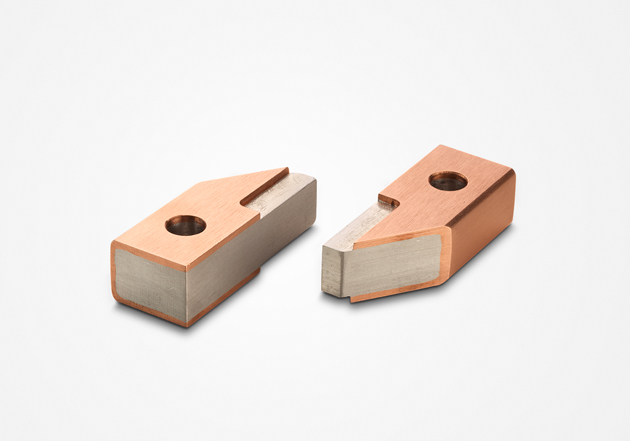

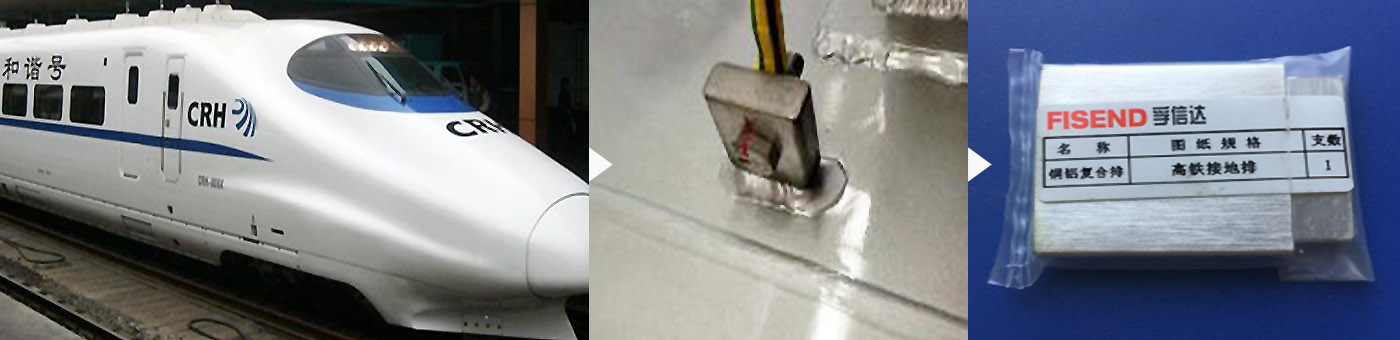

Main uses

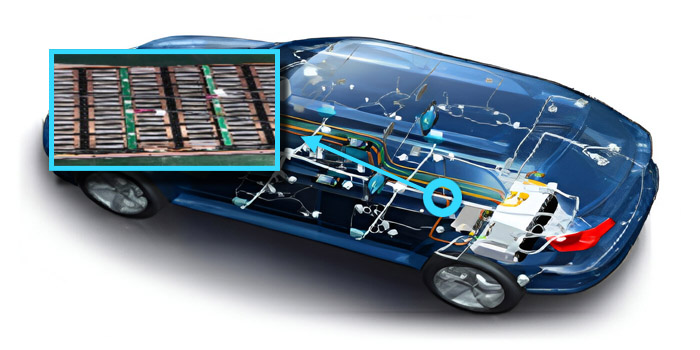

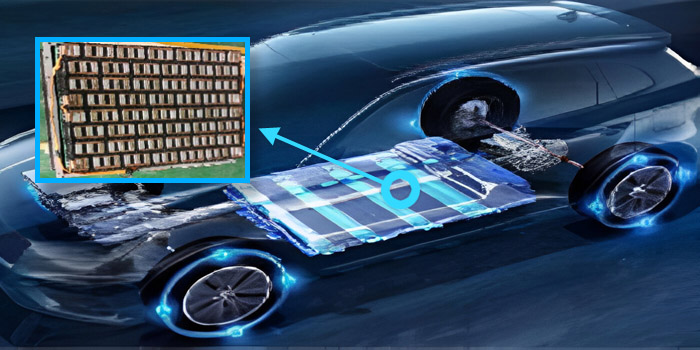

Automotive

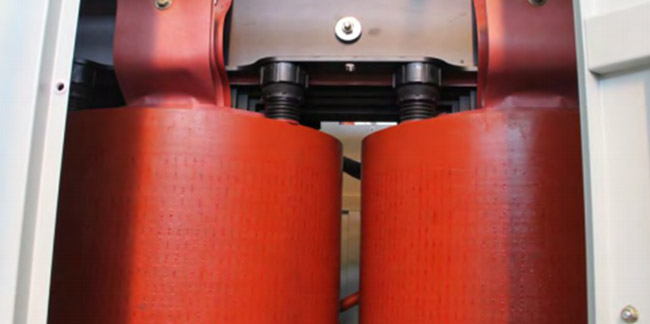

Electrical equipment

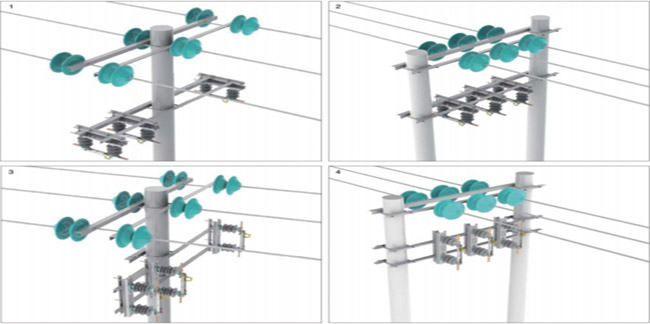

High Speed Rail/Subway

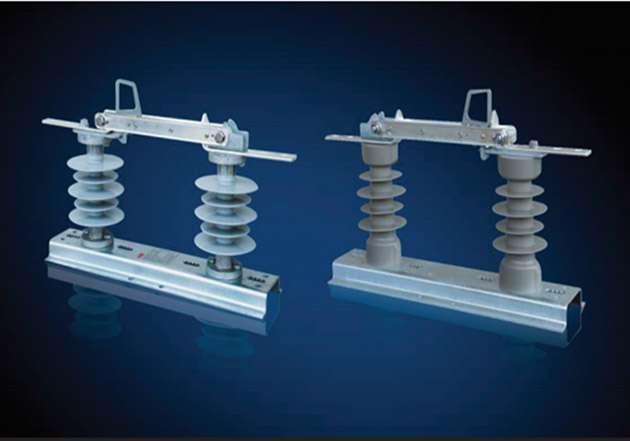

Transformer and outdoor isolation switch

Wind power generation equipment

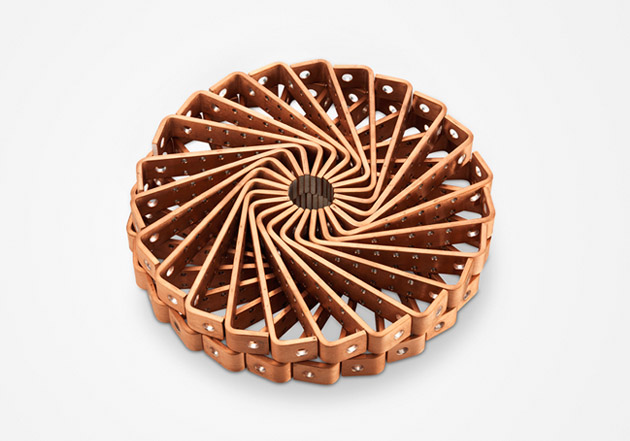

Automotive

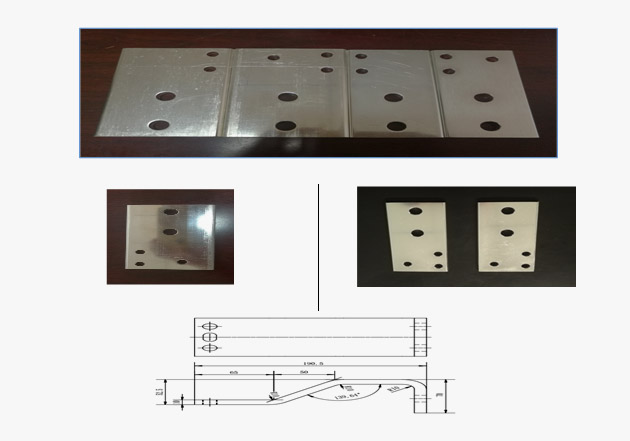

Main specifications

Width 15 to 50 mmApplications

- Busbars for automotive battery pack conductive applications

- Reduced weight of battery packs to save energy and cost

- Cost savings of more than 20% and weight savings of 50% compared to copper busbars