CCA

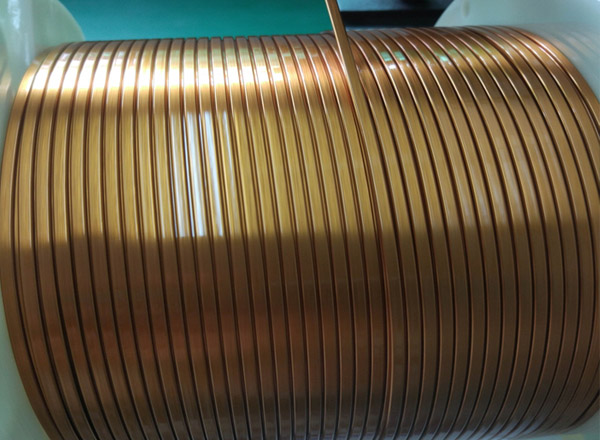

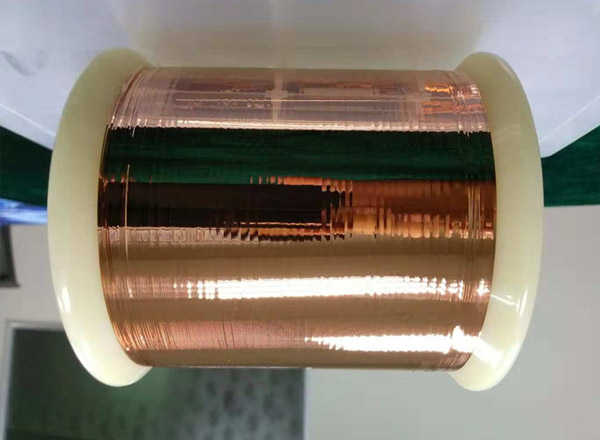

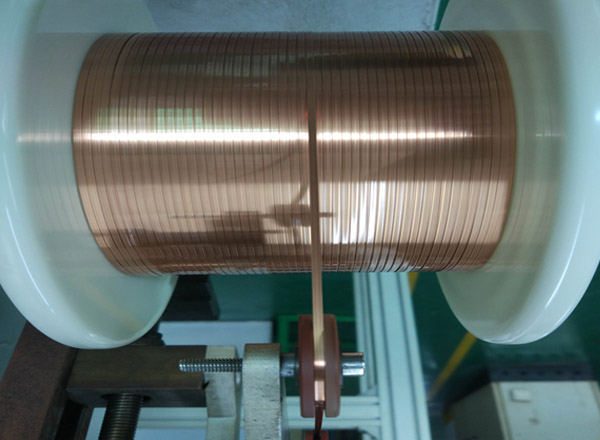

Copper Clad Aluminium Bimetal Horizontal continuous cast copper aluminum coil

Types and Characteristics

Move left and right to check.

Move left and right to check.| Polyurethane | Symbol | Heat resistance classification | Manufacturing range | Characteristics | Application | Remarks |

|---|---|---|---|---|---|---|

| Polyurethane Enameled Copper clad Wire | UEW | Type F(155℃) Type H(180℃) |

0.08 ~ 0.7mm |

|

Small motors, etc. | Type 1 ~ Type 3 |

| Polyurethane Enameled Copper clad Aluminum Wire | PEW | Class F(155℃) | 0.08 ~ 0.7mm |

|

Electronic devices, small motors, etc. | Type 1 ~ Type 3 |

- Other enamel specifications can be supplied after consultation

- Skin Effect : The higher the frequency, the greater the resistance at the center of the conductor, and the current flows to the outer edge of the conductor.

- CCA WIRE is efficient for high frequencies above 100Khz.

UEW Wire Specifications

Move left and right to check.

Move left and right to check.| Conductor | Min. film thickness/mm | Maximum outer diameter/mm | Minimum breakdown voltage at room temperature (effective value, V) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Conductor | Tolerance | CCAW/ | CCAW/ | CCAW/ | ||||||

| ±/mm | 1UEW | 2UEW | 3UEW | 1UEW | 2UEW | 3UEW | 1UEW | 2UEW | 3UEW | |

| 0.08 | 0.003 | 0.009 | 0.005 | 0.003 | 0.12 | 0.103 | 0.097 | 2000 | 1100 | 700 |

| 0.09 | 0.003 | 0.009 | 0.005 | 0.003 | 0.13 | 0.113 | 0.107 | 2000 | 1100 | 700 |

| 0.1 | 0.003 | 0.009 | 0.005 | 0.003 | 0.14 | 0.125 | 0.118 | 2000 | 1100 | 700 |

| 0.11 | 0.003 | 0.009 | 0.005 | 0.003 | 0.15 | 0.135 | 0.128 | 2000 | 1100 | 700 |

| 0.12 | 0.003 | 0.01 | 0.006 | 0.004 | 0.162 | 0.147 | 0.139 | 2200 | 1300 | 850 |

| 0.13 | 0.003 | 0.01 | 0.006 | 0.004 | 0.172 | 0.157 | 0.149 | 2200 | 1300 | 850 |

| 0.14 | 0.003 | 0.01 | 0.006 | 0.004 | 0.182 | 0.167 | 0.159 | 2200 | 1300 | 850 |

| 0.15 | 0.003 | 0.01 | 0.006 | 0.004 | 0.192 | 0.177 | 0.169 | 2200 | 1300 | 850 |

| 0.16 | 0.003 | 0.011 | 0.007 | 0.005 | 0.204 | 0.189 | 0.181 | 2200 | 1300 | 850 |

| 0.17 | 0.003 | 0.011 | 0.007 | 0.005 | 0.214 | 0.199 | 0.191 | 2200 | 1300 | 850 |

| 0.18 | 0.003 | 0.012 | 0.008 | 0.005 | 0.226 | 0.211 | 0.202 | 2400 | 1600 | 1000 |

| 0.19 | 0.003 | 0.012 | 0.008 | 0.005 | 0.236 | 0.221 | 0.212 | 2400 | 1600 | 1000 |

| 0.2 | 0.003 | 0.012 | 0.008 | 0.005 | 0.246 | 0.231 | 0.222 | 2400 | 1600 | 1000 |

| 0.21 | 0.003 | 0.012 | 0.008 | 0.005 | 0.256 | 0.241 | 0.232 | 2400 | 1600 | 1000 |

| 0.22 | 0.003 | 0.012 | 0.008 | 0.005 | 0.266 | 0.252 | 0.243 | 2400 | 1600 | 1000 |

| 0.23 | 0.004 | 0.013 | 0.009 | 0.006 | 0.278 | 0.264 | 0.255 | 2400 | 1600 | 1000 |

| 0.24 | 0.004 | 0.013 | 0.009 | 0.006 | 0.288 | 0.274 | 0.265 | 2400 | 1600 | 1000 |

| 0.25 | 0.004 | 0.013 | 0.009 | 0.006 | 0.298 | 0.284 | 0.275 | 2400 | 1600 | 1000 |

| 0.26 | 0.004 | 0.013 | 0.009 | 0.006 | 0.31 | 0.294 | 0.285 | 2400 | 1600 | 1000 |

| 0.27 | 0.004 | 0.013 | 0.009 | 0.006 | 0.32 | 0.304 | 0.295 | 2400 | 1600 | 1000 |

| 0.28 | 0.004 | 0.013 | 0.009 | 0.006 | 0.33 | 0.314 | 0.305 | 2400 | 1600 | 1000 |

| 0.29 | 0.004 | 0.013 | 0.009 | 0.006 | 0.34 | 0.324 | 0.315 | 2400 | 1600 | 1000 |

| 0.3 | 0.004 | 0.014 | 0.01 | 0.007 | 0.352 | 0.337 | 0.327 | 2800 | 2000 | 1400 |

| 0.32 | 0.004 | 0.014 | 0.01 | 0.007 | 0.372 | 0.357 | 0.347 | 2800 | 2000 | 1400 |

| 0.35 | 0.004 | 0.014 | 0.01 | 0.007 | 0.402 | 0.387 | 0.377 | 2800 | 2000 | 1400 |

| 0.37 | 0.005 | 0.014 | 0.01 | 0.007 | 0.424 | 0.407 | 0.397 | 2800 | 2000 | 1400 |

| 0.4 | 0.005 | 0.015 | 0.011 | 0.007 | 0.456 | 0.439 | 0.429 | 2800 | 2000 | 1400 |

| 0.45 | 0.005 | 0.016 | 0.011 | 0.007 | 0.508 | 0.49 | 0.479 | 2800 | 2000 | 1400 |

| 0.5 | 0.005 | 0.017 | 0.012 | 0.008 | 0.56 | 0.542 | 0.531 | 3050 | 2150 | 1450 |

| 0.55 | 0.005 | 0.017 | 0.012 | 0.008 | 0.62 | 0.592 | 0.581 | 3050 | 2150 | 1450 |

| 0.6 | 0.006 | 0.017 | 0.012 | 0.008 | 0.672 | 0.644 | 0.632 | 3050 | 2150 | 1450 |

| 0.65 | 0.007 | 0.018 | 0.012 | / | 0.724 | 0.694 | / | 3050 | 2150 | / |

| 0.7 | 0.007 | 0.019 | 0.013 | / | 0.776 | 0.746 | / | 3050 | 2150 | / |

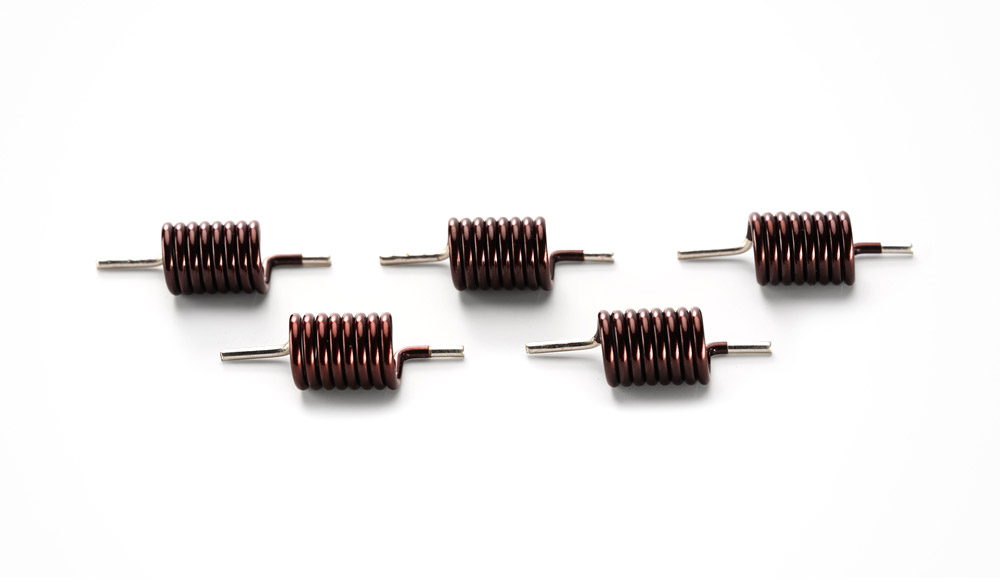

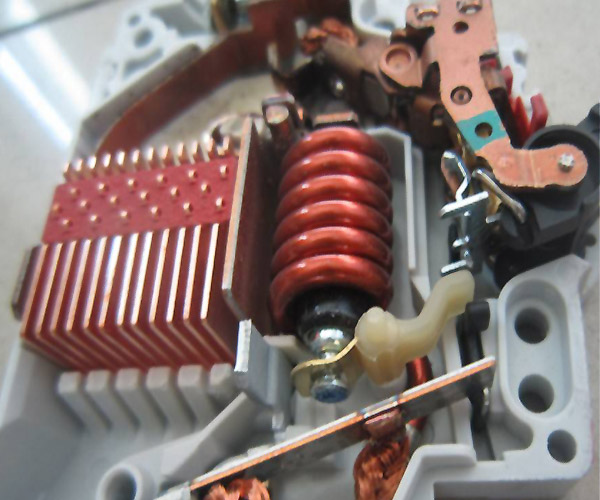

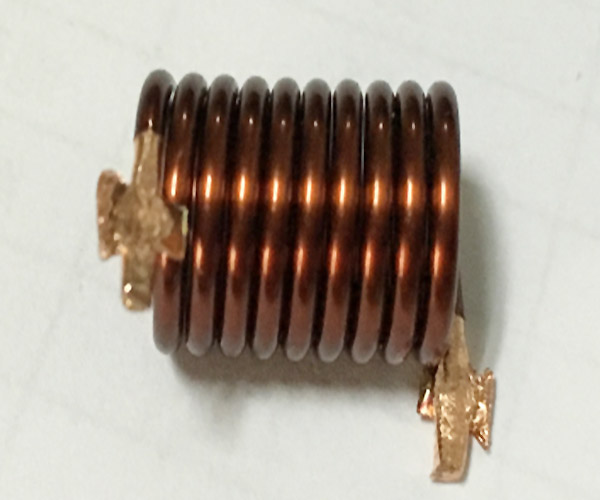

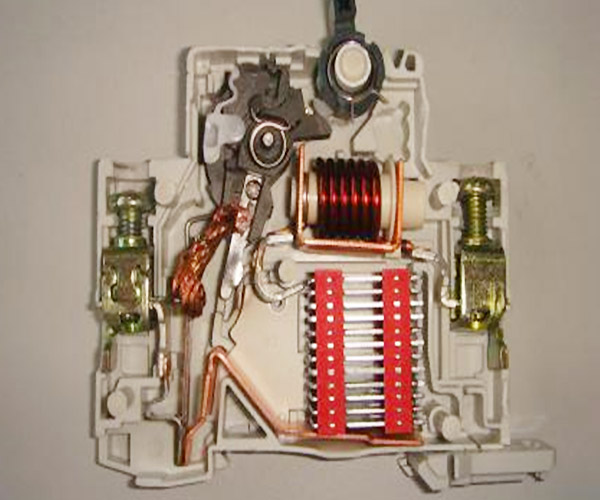

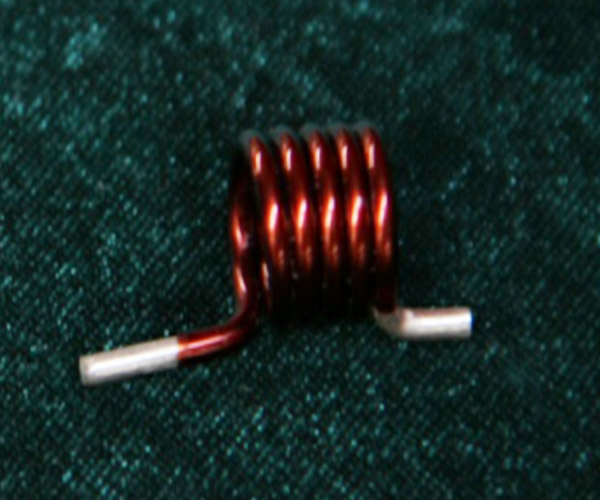

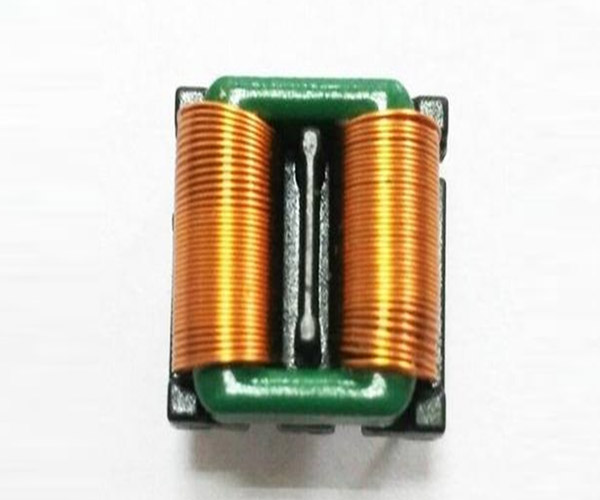

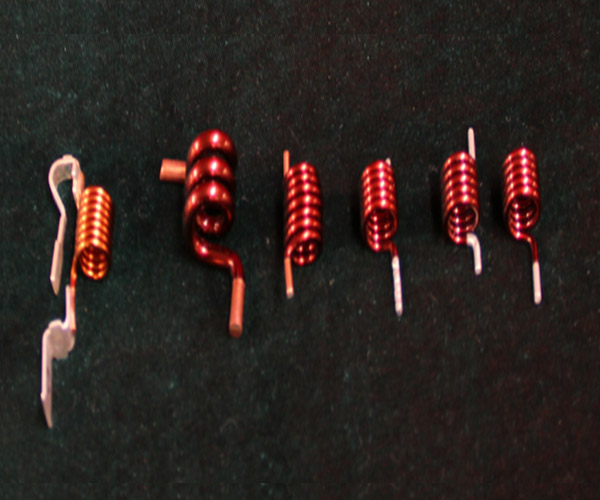

Application of CCA WIRE

Motor, Switch, Transformer, Transformer, Transformer, etc.