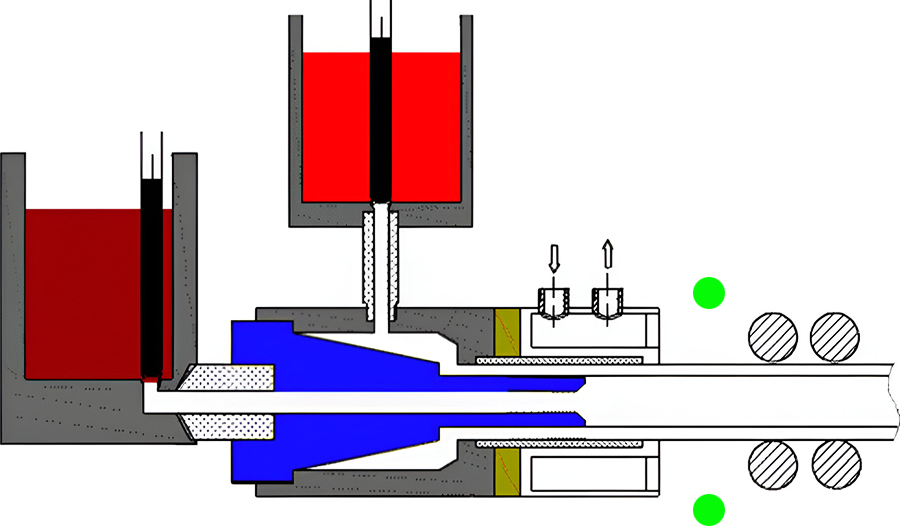

- ① Molten copper liquid enters a vacuum composite furnace to form a copper pipe, and then molten aluminum liquid enters the copper pipe.

- ② Aluminum and copper on the inner wall of the surface of the molten copper pipe melt together at high temperatures to form a surface (interface) fusion.

- ③ Copper and aluminum that formed the surface fusion form a new compound through a chemical reaction, and a new bond (metallurgical bond) between atoms is completed, which results in a surface (interface) reaction.

- ④ The two metal liquids pass through the composite mold and undergo accurate cooling for the second and third time to form a stable crystal zone (this zone is a sealed zone filled with metal liquid and gas cannot enter), and when the solidified bar (sheared billet) is taken out through the moving processor, the copper aluminum billet is completed.

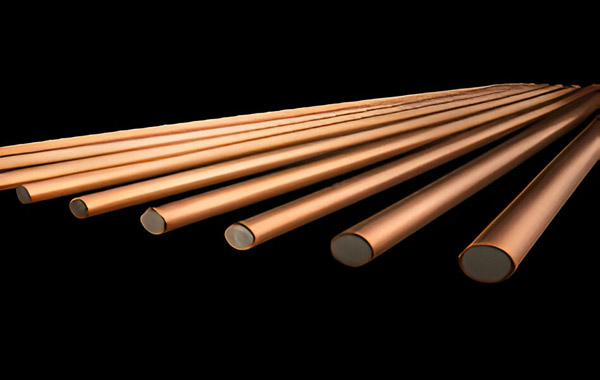

CCA

Copper Clad Aluminium Bimetal Horizontal continuous casting copper aluminum rod/terminal

Rod Specifications

Move left and right to check.

Move left and right to check.| Order | Diameter(mm) | Material condition | Copper volume ratio | Density |

|---|---|---|---|---|

| 1 | Φ10.4 | A,H | 30% / 25% | 4.56/4.25 |

| 2 | Φ10.7 | A,H | 30% / 25% | 4.56/4.25 |

| 3 | Φ11.3 | A,H | 30% / 25% | 4.56/4.25 |

| 4 | Φ11.6 | A,H | 30% / 25% | 4.56/4.25 |

| 5 | Φ11.9 | A,H | 30% / 25% | 4.56/4.25 |

| 7 | Φ12 | A,H | 30% / 25% | 4.56/4.25 |

| 8 | Φ12.5 | A,H | 30% / 25% | 4.56/4.25 |

| 9 | Φ12.8 | A,H | 30% / 25% | 4.56/4.25 |

| 11 | Φ13.1 | A,H | 30% / 25% | 4.56/4.25 |

| 12 | Φ13.4 | A,H | 30% / 25% | 4.56/4.25 |

| 15 | Φ13.7 | A,H | 30% / 25% | 4.56/4.25 |

| 16 | Φ14 | A,H | 30% / 25% | 4.56/4.25 |

| 17 | Φ15.2 | A,H | 30% / 25% | 4.56/4.25 |

| 18 | Φ15.8 | A,H | 30% / 25% | 4.56/4.25 |

| 19 | Φ16 | A,H | 30% / 25% | 4.56/4.25 |

| 20 | Φ16.5 | A,H | 30% / 25% | 4.56/4.25 |

| 21 | Φ17 | A,H | 30% / 25% | 4.56/4.25 |

| 22 | Φ18 | A,H | 30% / 25% | 4.56/4.25 |

| 23 | Φ20 | A,H | 25% | 4.25 |

| 24 | Φ22 | A,H | 25% | 4.25 |

| 25 | Φ23 | A,H | 25% | 4.25 |

| 26 | Φ24 | A,H | 25% | 4.25 |

| 27 | Φ24.9 | A,H | 25% | 4.25 |

| 28 | Φ25 | A,H | 25% | 4.25 |

| 29 | Φ26 | A,H | 25% | 4.25 |

| 30 | Φ27 | A,H | 25% | 4.25 |

| 31 | Φ28 | A,H | 25% | 4.25 |

| 32 | Φ29 | A,H | 25% | 4.25 |

| 33 | Φ29.8 | A,H | 25% | 4.25 |

| 34 | Φ30 | A,H | 25% | 4.25 |

| 35 | Φ32 | A,H | 25% | 4.25 |

※ Other non-standards are subject to consultation

Terminal specifications

Move left and right to check.

Move left and right to check.| Rank | Size | Manufacturing(㎣) | Density(g/㎤) | Weight(g/piece) |

|---|---|---|---|---|

| 1 | DTBL-16 | 4,016.15 | 4.25 | 17.07 |

| 2 | DTBL-25 | 5,904.51 | 4.25 | 25.09 |

| 3 | DTBL-35 | 8,443.18 | 4.25 | 35.88 |

| 4 | DTBL-50 | 11,899.62 | 4.25 | 50.57 |

| 5 | DTBL-70 | 16,106.95 | 4.25 | 68.45 |

| 6 | DTBL-95 | 24,847.78 | 4.25 | 105.6 |

| 7 | DTBL-120 | 30,458.99 | 4.25 | 129.45 |

| 8 | DTBL-150 | 38,933.91 | 4.25 | 165.47 |

| 9 | DTBL-185 | 45,802.65 | 4.25 | 194.66 |

| 10 | DTBL-240 | 60,192.16 | 4.25 | 255.82 |

| 11 | DTBL-300 | 90,186.26 | 4.25 | 383.29 |

※ 1 Hole is the standard size